App Store

Google Play

OpsLink brings powerful drilling-fluid management to your iPhone and iPad. Built for drilling-fluid engineers, mud logging specialists, and drilling operations teams in oil & gas, the app puts your entire mud system at your fingertips whether you’re in the office, on the rig floor, or halfway up the derrick.

Whether you’re optimizing hole cleaning, preventing kicks, troubleshooting losses, or simply logging daily mud-checks, Muddy Software gives drilling fluid teams the tools they need to improve efficiency, enhance compliance, and reduce non-productive time.

Every line of code serves a meaningful purpose

Built for real people solving real problems

Pushing boundaries with cutting-edge research

Uncompromising quality in every detail

Because you’re often halfway up the derrick or in the doghouse, OpsLink is 100% web-based and mobile-responsive. We support:

OpsLink is purpose-built for drilling-fluids and mud-logging workflows.

Unlike generic AI tools, it ingests your actual mud-engineer daily reports—MD/TVD, ECD vs. depth, rheology logs, pump-pressure and flow-line timestamps, solids-control runs, cost tables, and field notes—and correlates them with hole geometry and casing programs.

You can also chat with your well’s personal AI assistant—think “PhD in Drilling Engineering” on demand—leveraging real-time data to answer questions like:

“What’s driving the ΔECD spike at 17½″?”

“Recommend a gel-strength curve for this shaley section.”

Our domain-specific NLP and ML models have been trained on thousands of real drilling-fluids records, so OpsLink can:

Automatically detect anomalies in mud weight or gel strength that could indicate barite sag or wellbore instability.

Generate targeted recommendations (e.g. tweak viscosity modifiers, swap shaker screen meshes, optimize bit-nozzle configuration) based on your hole section and formation lithology.

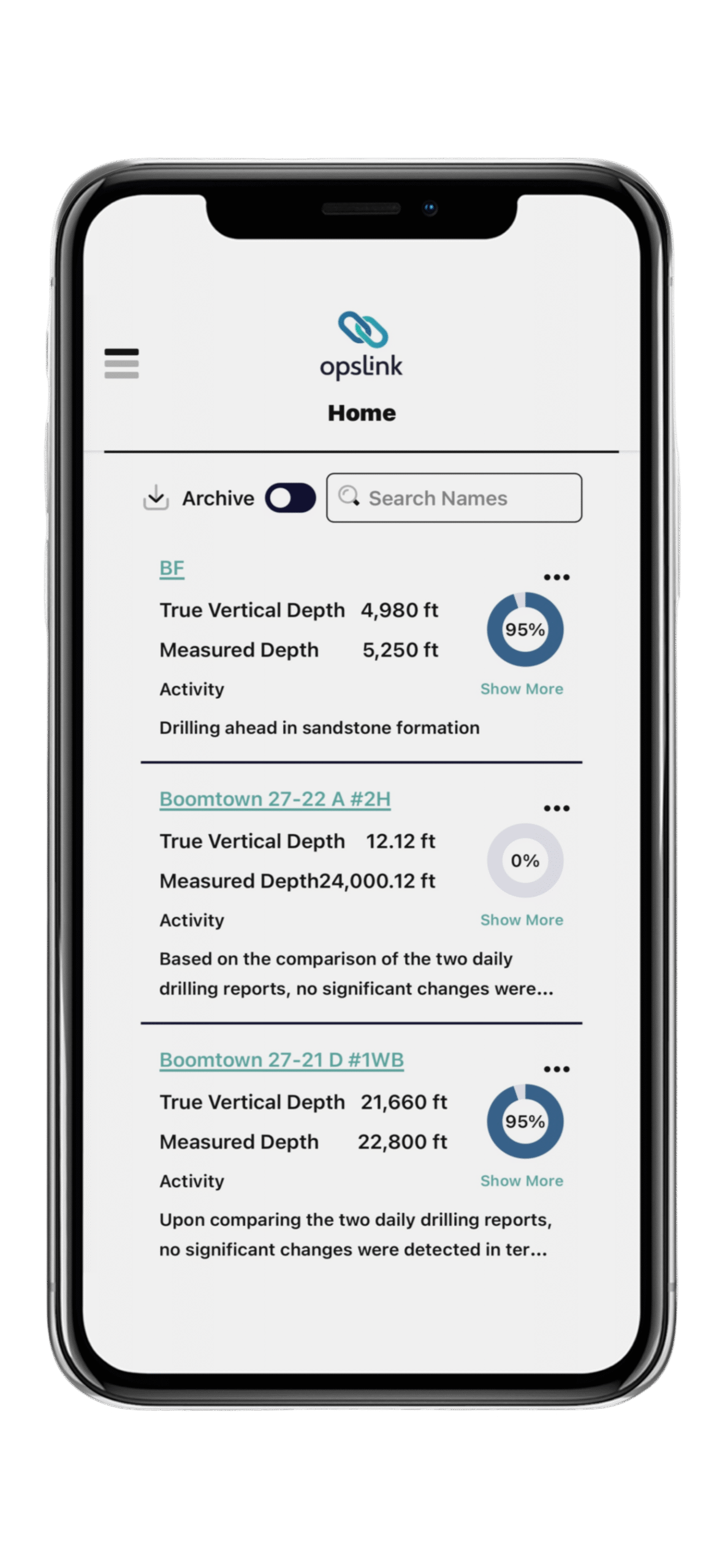

Summarize operational changes (“Drilling ahead in sandstone; no significant ECD upticks; recommend 140-mesh shaker screens until next trip”) so supervisors see the bottom-line impact at a glance.

Visualize real-time KPIs—TVD vs. MD progress, mud-weight trends, total pump-hours, solids inventory, cost burn-rate—across all wells in one pane.

In short, OpsLink isn’t a black-box chatbot: it’s a fully integrated, drilling-fluids intelligence layer that sits on top of your rig-site data and speaks your language.

We know well data is highly sensitive. OpsLink employs:

End-to-end AES-256 encryption (in transit and at rest).

Role-based access controls so mud engineers, drillers, superintendents or clients see only what they’re permitted.

Dedicated data partitioning (each operator’s data lives in its own vault).

Continuous audit logging of every login, report view, export or AI query

OpsLink’s AI stack combines:

Natural Language Processing tuned to industry jargon—“lose returns,” “gel strength,” “pump-off”—so it accurately parses your field notes and daily narratives.

Anomaly-detection engines that continuously compare incoming daily reports against expected baselines (e.g. ECD vs. MD, shaker screen mesh runs) and flag deviations in real time.

Because you’re often halfway up the derrick or in the doghouse, OpsLink is 100% web-based and mobile-responsive.

We support:

Desktop browsers: Chrome, Firefox, Edge, and Safari on Windows 10+, macOS 10.14+, and most Linux distros.

Mobile: Safari on iOS 14+ and Chrome on Android 9+.

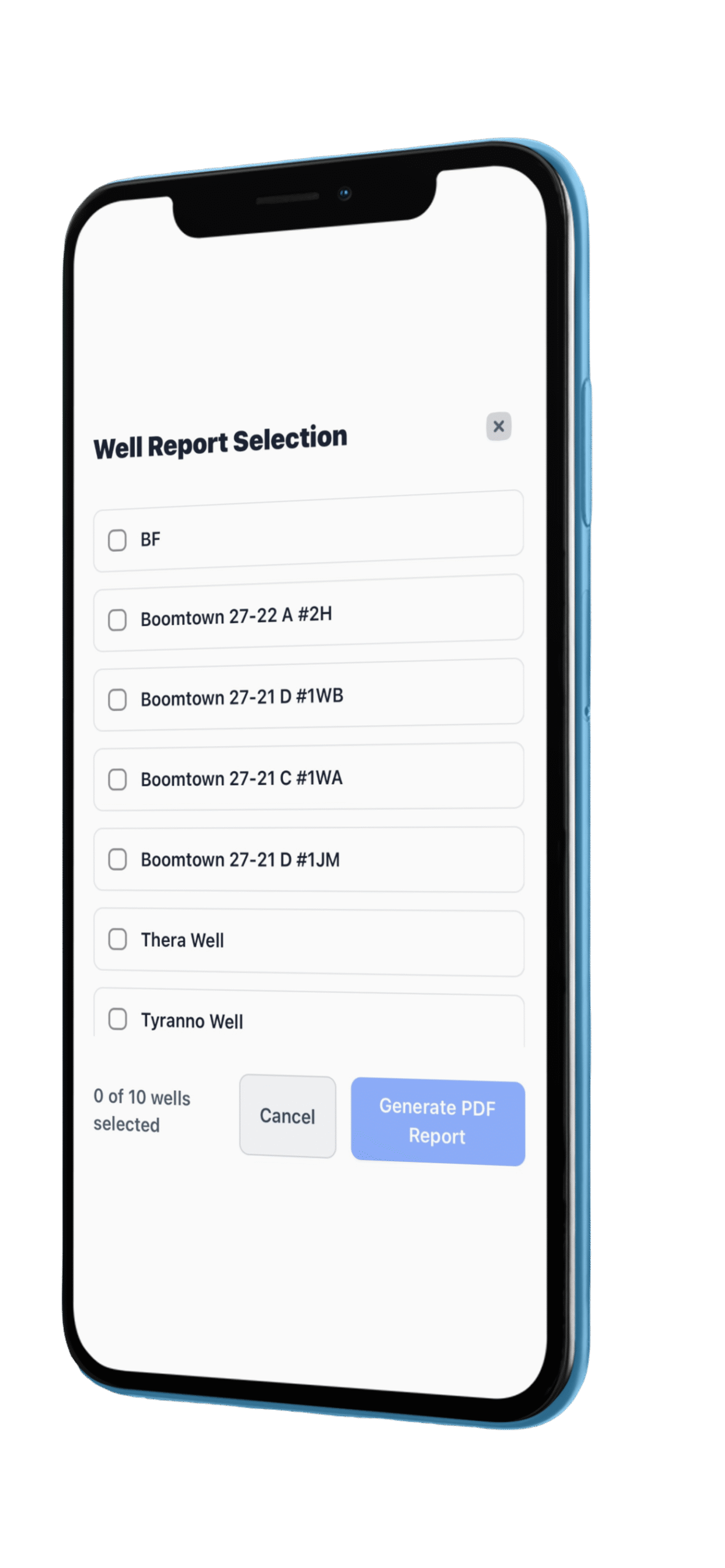

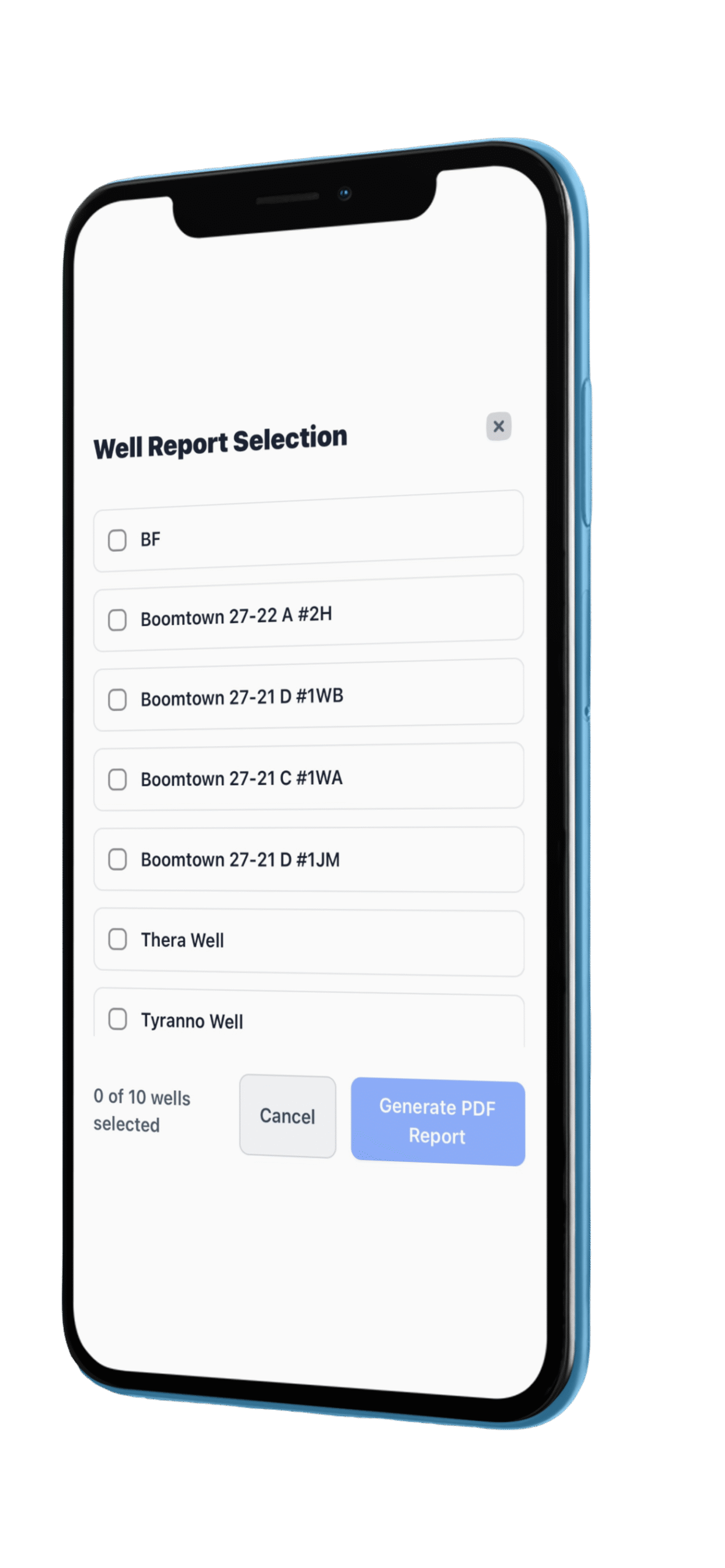

Native apps (optional): iOS App Store version which lets you review AI summaries offline and sync when you’re back on-line.

How often do you release updates?

We follow a DevOps cadence tailored for rig-site reliability:

• Minor fixes & performance tweaks: deployed weekly (zero downtime).

• New features and UI enhancements: shipped monthly (e.g., new analytics widgets, ML-model improvements).

• Major platform upgrades—including entirely new modules such as directional-drilling integration or custom LCM-analysis tools—are rolled out quarterly.

We follow a DevOps cadence tailored for rig-site reliability:

• Minor fixes & performance tweaks: deployed weekly (zero downtime).

• New features and UI enhancements: shipped monthly (e.g. new analytics widgets, ML-model improvements).

• Major platform upgrades—including entirely new modules such as directional-drilling integration or custom LCM-analysis tools—are rolled out quarterly.

OpsLink offers a dedicated email for high-priority or technical-support tickets (info@opslink.ai)

OpsLink is purpose-built for drilling-fluids and mud-logging workflows.

Unlike generic AI tools, it ingests your actual mud-engineer daily reports—MD/TVD, ECD vs. depth, rheology logs, pump-pressure and flow-line timestamps, solids-control runs, cost tables, and field notes—and correlates them with hole geometry and casing programs.

You can also chat with your well’s personal AI assistant—think “PhD in Drilling Engineering” on demand—leveraging real-time data to answer questions like:

“What’s driving the ΔECD spike at 17½″?”

“Recommend a gel-strength curve for this shaley section.”

Our domain-specific NLP and ML models have been trained on thousands of real drilling-fluids records, so OpsLink can:

Automatically detect anomalies in mud weight or gel strength that could indicate barite sag or wellbore instability.

Generate targeted recommendations (e.g. tweak viscosity modifiers, swap shaker screen meshes, optimize bit-nozzle configuration) based on your hole section and formation lithology.

Summarize operational changes (“Drilling ahead in sandstone; no significant ECD upticks; recommend 140-mesh shaker screens until next trip”) so supervisors see the bottom-line impact at a glance.

Visualize real-time KPIs—TVD vs. MD progress, mud-weight trends, total pump-hours, solids inventory, cost burn-rate—across all wells in one pane.

In short, OpsLink isn’t a black-box chatbot: it’s a fully integrated, drilling-fluids intelligence layer that sits on top of your rig-site data and speaks your language.

We know well data is highly sensitive. OpsLink employs:

End-to-end AES-256 encryption (in transit and at rest).

Role-based access controls so mud engineers, drillers, superintendents or clients see only what they’re permitted.

Dedicated data partitioning (each operator’s data lives in its own vault).

Continuous audit logging of every login, report view, export or AI query

OpsLink’s AI stack combines:

Natural Language Processing tuned to industry jargon—“lose returns,” “gel strength,” “pump-off”—so it accurately parses your field notes and daily narratives.

Anomaly-detection engines that continuously compare incoming daily reports against expected baselines (e.g. ECD vs. MD, shaker screen mesh runs) and flag deviations in real time.

Because you’re often halfway up the derrick or in the doghouse, OpsLink is 100% web-based and mobile-responsive.

We support:

Desktop browsers: Chrome, Firefox, Edge, and Safari on Windows 10+, macOS 10.14+, and most Linux distros.

Mobile: Safari on iOS 14+ and Chrome on Android 9+.

Native apps (optional): iOS App Store version which lets you review AI summaries offline and sync when you’re back on-line.

How often do you release updates?

We follow a DevOps cadence tailored for rig-site reliability:

• Minor fixes & performance tweaks: deployed weekly (zero downtime).

• New features and UI enhancements: shipped monthly (e.g., new analytics widgets, ML-model improvements).

• Major platform upgrades—including entirely new modules such as directional-drilling integration or custom LCM-analysis tools—are rolled out quarterly.

We follow a DevOps cadence tailored for rig-site reliability:

• Minor fixes & performance tweaks: deployed weekly (zero downtime).

• New features and UI enhancements: shipped monthly (e.g. new analytics widgets, ML-model improvements).

• Major platform upgrades—including entirely new modules such as directional-drilling integration or custom LCM-analysis tools—are rolled out quarterly.

OpsLink offers a dedicated email for high-priority or technical-support tickets (info@opslink.ai)